EXPECTED RESULTS

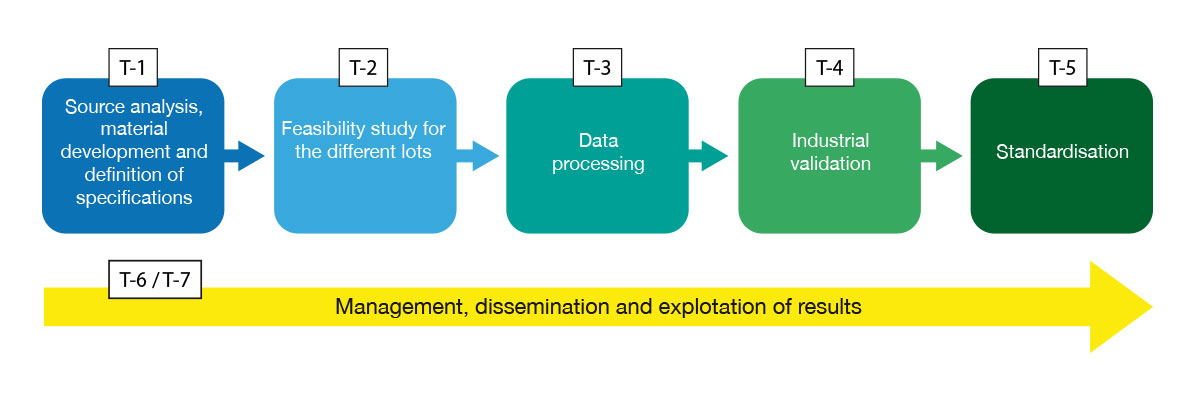

The main aim is to develop an expert system to select process variables for recycled materials based on their characteristics (fluidity, density, etc.).

This will involve creating training and reference material around the processing of recycled materials by injection moulding, ready to serve as a reference for injection moulding professionals wishing to get started in the processing of materials. The project will end with the publication of a “White Paper on the processing of recycled materials by injection moulding”.

The aim is also to develop a methodology that boosts the competitiveness of companies through:

- Better quality recycled material, regardless of its origin (post-industrial or post-consumer), with characteristics comparable to virgin material.

- Better knowledge of the optimum transformation parameters for this type of material.

- Ability to work with local suppliers and customers, reducing not only the carbon footprint from transportation but also dependence on distant countries and large multinationals.

The SERA project is aligned with European and national industrial policy strategies and R&D&I policies. The expected results are aligned with Goal 9 of the Sustainable Development Goals (SDGs), on industry, innovation and infrastructure, and also contribute towards the reuse of plastic waste.

Implementation period: July 2022 – April 2023

Aclima‘s role is to coordinate the project’s communication and dissemination activities and organise a conference on the project’s scope.

Participants. The consortium that will develop the SERA project is made up of the Innovation Business Partnership formed by the Spanish Plastics Centre (CEP) (which, as the project leader, will coordinate the activities), and Aclima, which is in charge of disseminating the project tasks; Leartiker Technology Centre, which will be entrusted with generating and treating process data and developing the white book on the processing of recycled materials; and the companies Citsalp, which will identify and develop recycled materials and ensure they are characterised correctly, and Plásticos Clossa and SMP Ibérica, which are responsible for scalability of the work process in the pilot plant at industrial level and also for validating the white paper.

The project is funded by the Ministry of Industry, Trade and Tourism’s programme to support Innovation Business Partnerships (AEI), which is part of the Recovery, Transformation and Resilience Plan, with a view to improving the competitiveness of small- and medium-sized companies.