The low recycling rate for plastic waste leads to significant losses for the economy and a high impact on the environment. Major efforts are needed to reach the European Commission’s target of 10 million tonnes of recycled polymers recovered annually by 2025 and 2030.

PARTICIPATING ENTITIES

FINANCING ENTITIES

DESCRIPTION OF THE PROJECT

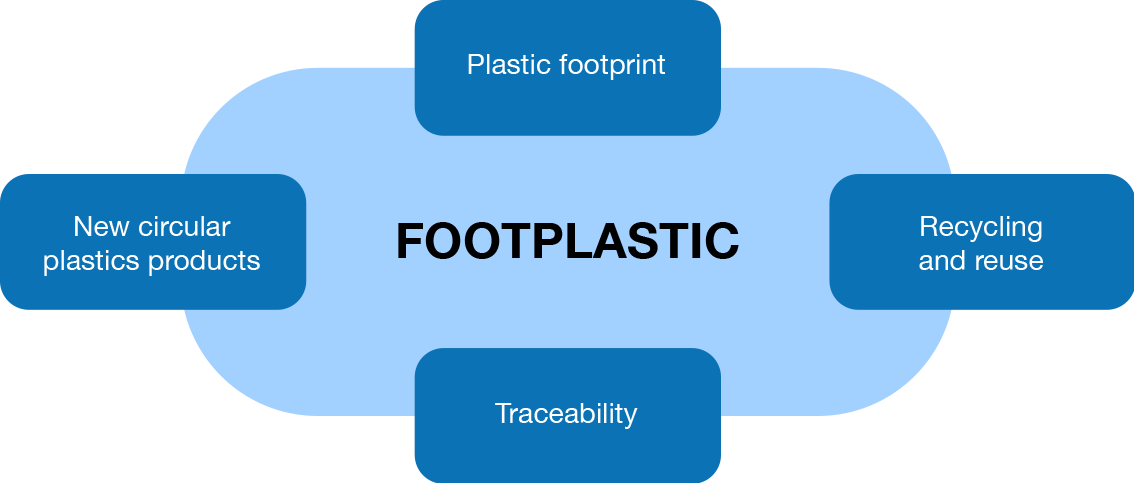

Given the problem of circularity of plastic flows and the scarcity of data to assess plastic spills, the FOOTPLASTIC project seeks to improve the use of plastic waste as a resource (circular economy), to help calculate and account for recycled materials, and to stimulate innovation and technology throughout the value chain.

In this context, this project encompasses 4 major developments:

- New measurement methodology to calculate plastic footprint at corporate level (FOOTPLASTIC methodology), in order to take informed actions aimed at circularising the plastics value chain.

- FOOTPLASTIC Platform technological development; a 360º traceability IoT/BlockChain platform for digital pre- and post-industrial plastic waste collection, recycling and reuse.

- Generate new recovered technical composites certified by Standard UNE-EN 15343:2008, ready to be reintroduced into the plastics industry.

- Manufacture new products, incorporating the new FOOTPLASTIC recovered technical composites in their formulation.

GOALS

- Promote a circular economy in the plastics industry.

- Increase the use of secondary raw materials in the industry.

- Provide recycled plastics suitable for industry requirements.

- Improve the environmental information and footprint for both products and organisations.

EXPECTED RESULTS

Thanks to the FOOTPLASTIC project, industrial companies in the Basque Country will count on methodologies to calculate and evaluate their plastic footprint, along with an interactive tool for characterisation and evaluation that will make it easier to identify and apply the best calculation systems at different levels throughout the territory.

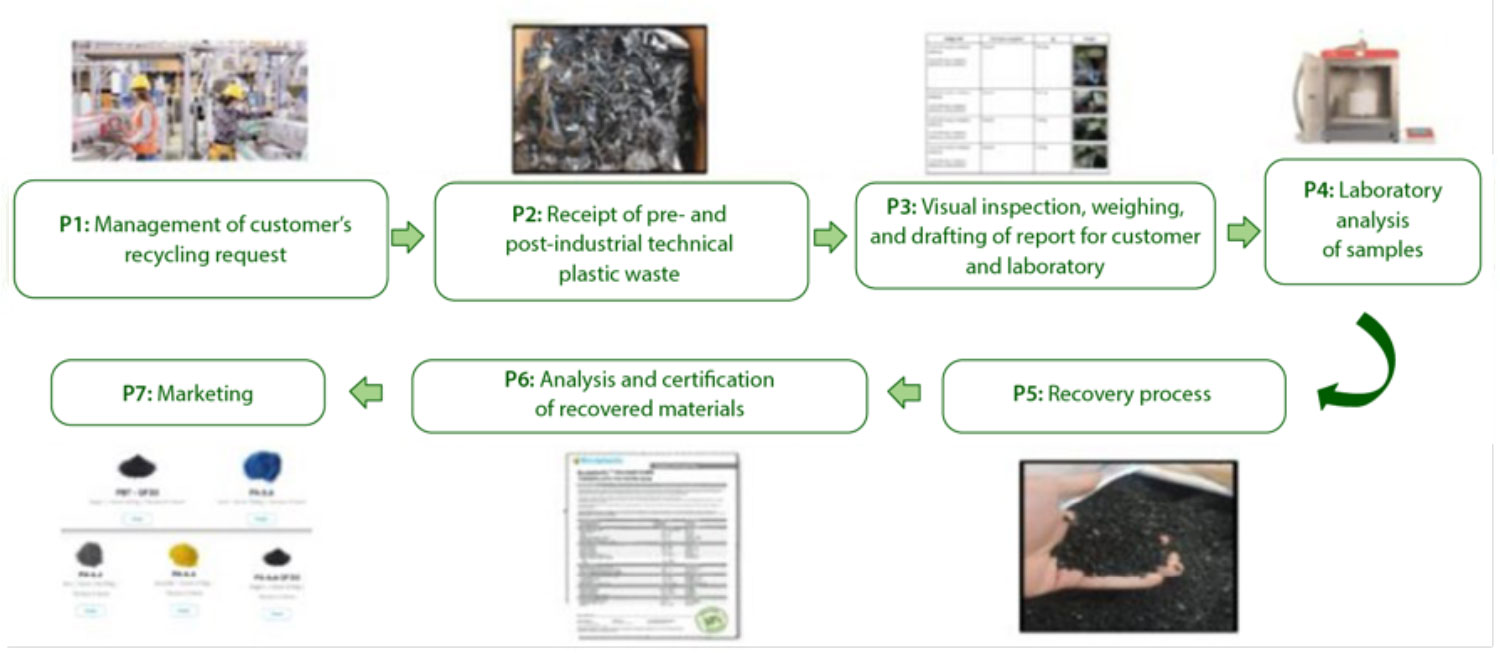

The FOOTPLASTIC platform will make it possible to manage production, logistics and administrative processes, oversee the traceability of products, materials and machinery, and also ensure they have the necessary intelligence, transforming large volumes of data into valuable information in order to improve efficiency and reduce operating costs. The focus will be on recovery and recycling processes that can guarantee and certify the quality of the new recovered technical composites.

Thanks to their contribution to the recovery of plastic waste, the expected results are aligned with both Goal 9 of the Sustainable Development Goals (SDGs), on industry, innovation and infrastructure, and with SDG 12, on responsible consumption and production.

PARTICIPANTS

The consortium to develop the FOOTPLASTIC project is made up of BIRZIPLASTIC, as the project leader, which will oversee not only the tasks related to the recovery of post-industrial plastic waste with a view to generating and marketing the new technical composites, but also those involved in analysis and digitalisation of the management and recycling of post-industrial plastic waste.

The FOOTPLASTIC Platform will be developed alongside the technology company KAYTEK, which is focused on developing the IoT/BlockChain platform.

For their part, the companies Plasticos CLOSSA, EMAÚS and FAGOR ELECTRÓNICA will supply plastic waste and validate the FOOTPLASTIC comprehensive circular solution. The following RVCTI members are also involved in the project: MIK S. Coop, as project coordinator and designer of the plastic footprint calculation methodology; Fundación GAIKER, for the development of more sustainable polymeric materials and better functional and structural performance; and Aclima, as an enabling hub for contrast groups and dissemination of results.

The project is funded by the Business R&D Support Aid Programme (Hazitek) to promote competitive Research and Development Projects. Project co-funded by the Basque Government and the European Union through the European Regional Development Fund 2021-2027 (ERDF).